Introduction

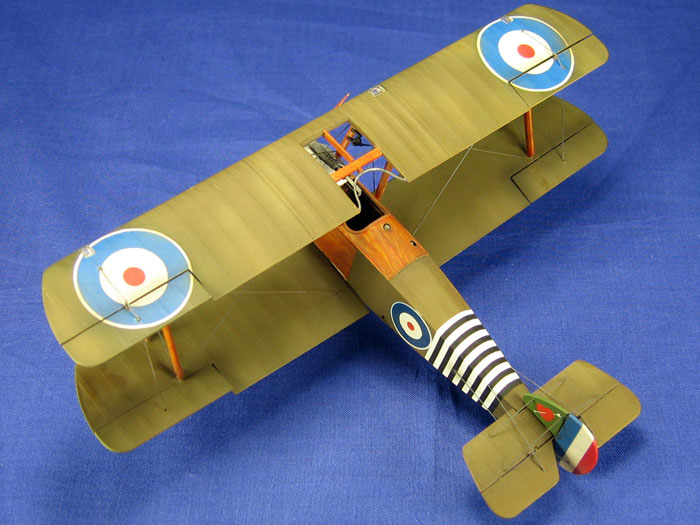

Having destroyed more enemy aircraft than any other fighter of World

War 1, the Sopwith Camel was one of the most successful designs of

the war. Entering service during the spring of 1917, it was a highly

maneuverable yet difficult aircraft to fly. With the engine, fuel

tanks, and guns up front it was very nose heavy, and that combined

with the action of the rotary Clerget engine gave it a fantastic

right-turn capability. Veteran pilots would use this to their

advantage, but a number of inexperienced pilots were killed in

accidents as well.

Eduardís new Camel kits have been out for a couple of years now, and

I decided to build one of them depicting Camel #B6313, the Camel

used by the famous Canadian ace William ďBillyĒ Barker for 46 of his

kills.

Construction

Construction of the cockpit, fuselage, and lower wings went

smoothly, but attaching the upper wing and struts was one of the

most frustrating exercises of my modeling life! The upper wing sits

forward of the lower wing, meaning its struts, all eight of them,

all sit at various angles.

While I love Eduardís kits, I thought the kit engineering here was

poor. All of the struts are molded with small nubs on the ends that

are supposed to fit into equally small recesses in the lower and

upper wings. The nubs arenít long enough to hold the weight of the

strut however, meaning thereís no way to glue a strut to the wing

without having to hold it with your hands while it dries. Since the

upper wing needs four of the struts in place to hold its weight, you

end up trying to glue four struts to the lower wing and then hold

them all upright while trying to position the upper wing on to them!

Unless you are an octopus, you quickly run out of hands. It didnít

matter what glue I used, I just never had enough hands to hold it

all together. I tried a homemade jig, but that didnít work either.

After a whole night of trying different methods and failing, I was

ready to pitch the whole kit in the trash! Finally I had success by

super-gluing the inboard struts onto the fuselage at what I thought

were the right angles, and then super-gluing the upper wing to them.

The four outboard struts were then attached after that, but as I

expected, the whole assembly wasnít as accurate as I would have

liked. The upper wing is too far forward and off to one side a bit,

but there was no way I was going to go back and try again! It was

truly a frustrating experience.

I think Eduard could easily fix the problem by turning the nubs on

the ends of the struts into proper pins that could hold the struts

up on their own. The modeler could then easily drill holes in the

wings, assemble the struts, glue them and the upper wing, and then

position the upper wing accurately as the whole assembly dried. Iíd

gladly putty over some small holes to avoid that experience again.

Once my upper wing rage subsided I finished up the construction,

adding the cowling and landing gear. I used EZ line for the rigging.

I left off the wheels, prop, and machine guns and the model was

thankfully ready to be painted.

Painting

After a primer coat of Mr. Surfacer 1000 was sprayed on the whole

aircraft, I sprayed Testors Acrylic Radome Tan on the undersides of

the fuselage and both wings to simulate Clear Doped Linen. To

simulate the khaki green color on the upper surfaces I used Tamiya

Olive Drab. I then added some Tamiya Dark Yellow to the Olive Drab

to tone it down a bit, and randomly sprayed some spots and streaks

on to the upper surfaces.

I brush-painted all of the Camelís wood parts using a three-step

procedure that I read about online. First the parts were painted

Testors Acrylic Wood, a beige color. Then Testors Acrylic Leather

and a small brush were used to paint wavy lines to simulate the

grain of the wood. Lastly a generous coat of Tamiya Clear Orange was

used to unify the first two steps, resulting in realistic looking

wood with a varnished gloss finish. The cowling and sheet metal

panels around the nose were brush-painted with Testors Aluminum. The

machine gun was painted Tamiya NATO Black and then dry-brushed with

Testors Steel. The rigging wires were painted Tamiya NATO Black.

I sprayed the entire model with Future to get it ready for the

decals.

Markings & Weathering

I used Eagle Strikeís ďSopwith F.1 Camels, Part 1Ē decals and they

went on flawlessly. I usually use Walthers Solvaset to get the

decals to sit down over any bumps or recesses, and the Eagle Strike

decals had no problems with it. I glued on the prop, wheels, and

machine gun and sprayed some Testors Enamel Flat Finish over the

whole aircraft to seal the decals and tone down the finish. Like

many modelers Iíve tried many flat finishes in search of the one

that creates the flattest finish and lately Iíve had very good

results with the Testor's Enamel Flat, sprayed right out of the

bottle with no thinning.

Using a small brush I used a thin wash of 50/50 Lamp Black/Raw Umber

to accentuate the recessed lines around the cowling and sheet metal

panels on the Camel's nose. I then airbrushed a very then mix of the

same mix around the flaps, wheels, where the wings and stabilizers

meet the fuselage, and especially around the engine and cowling to

add a bit more grime to the model.

My last step was to mist on a bit of Tamiya Desert Yellow around the

wheels and rear skid to simulate some dust and dirt.