Description

The XP-56 was Northrop’s response to a 1939

proposal for a high-speed fighter of “entirely new design.” The

other contenders were the Curtiss XP-55 and the Vultee XP-54. All

three designs featured pusher propellers, the goal being to reduce

drag and allow space in the nose for weaponry.

The XP-56 design incorporated a number of

unusual features. It was powered by a rear-mounted R-2800 radial

engine driving counter-rotating propellers.

The long, swept wing featured elevons (serving

as both elevators and ailerons) and split rudders, which were

operated by airflow through “aero boost ducts” on the wingtips. The

XP-56 was intended to carry four .50 calibre machine guns and two

20mm cannon, although these were never installed.

Two prototypes were built, but tests revealed

that Northrop’s design possessed some rather unpleasant flight

characteristics. The first XP-56 was destroyed on its fourth flight

and the second was grounded after only ten flights. Work on this

project was not wasted, however, as Northrop used the knowledge

gained from the XP-56 when developing the XB-35 a few years later.

Construction

A year or so ago, Hyperscale featured a very

detailed and positive

review

of Czech Model’s 1/48 scale limited-run kit of the XP-56. Since

getting back into modeling a couple years ago, I’d wanted to try my

hand at a limited-run kit. The XP-56 seemed like a relatively

simple one to start with.

The review here on Hyperscale includes a very

detailed explanation of what is in the kit. I was unable to take

any construction photos, so I would refer you to this excellent

article for a description of the interior bits. I will just try to

explain some of the steps I found to be a bit challenging.

Wings

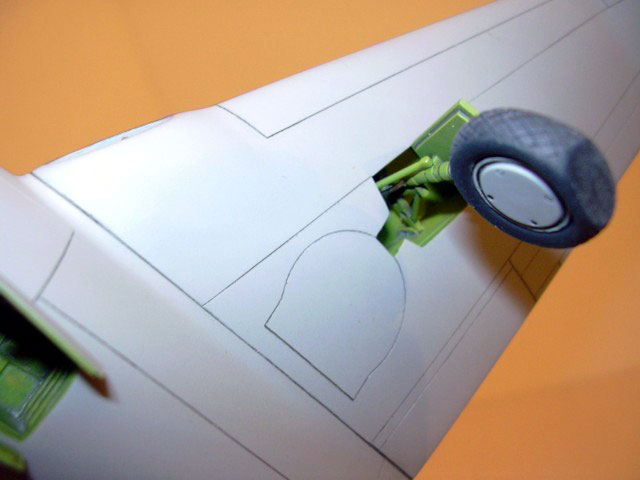

All the wing components fit together rather

well. The kit includes well-detailed resin inserts for the wheel

wells and cooling intakes at the wing roots. Both fit nicely,

although I did have to sand down the backside of the wheel wells

quite a bit so that the wing halves would fit together. Just to

spruce things up a bit, I added some wire mesh to the cooling

intakes and nav lights to the wing tips.

Almost as an afterthought, I decided to check

the fit of the main landing gear before proceeding with the rest of

the kit. The main gear on the XP-56 was a double-jointed affair,

similar to that on the F8F Bearcat. To replicate this, Czech Model

molded each main gear leg in two parts: an “L” shaped bracket that

attaches to the gear well (in two tiny spots), and the gear leg

itself that attaches to the bracket (again, in two tiny spots).

This seemed like a rather weak setup to me.

After pondering it for a while, I decided to

drill a hole in the top of the gear leg and insert a length of brass

tubing, basically extending the length of the gear leg. I then

drilled holes through the “L” shaped bracket directly into the resin

gear well. Later, during final assembly, I was able to mount the

extended main gear directly into these holes. This ensures that the

gear is solidly fixed to the wing.

Fuselage

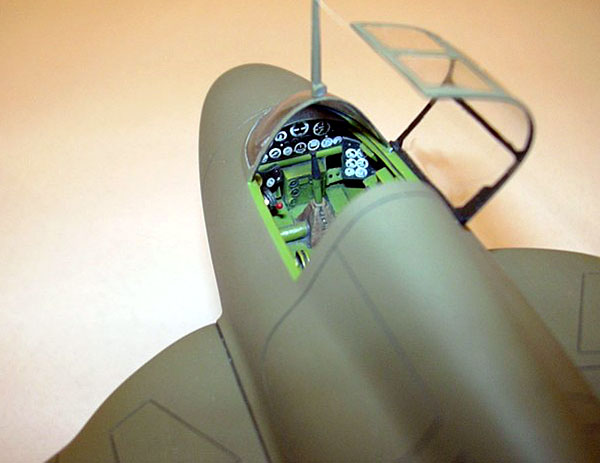

Next came the fuselage and cockpit. The main

components for the cockpit are three large resin castings: the

cockpit floor and aft bulkhead, both of which fit over the nose gear

well. The only guide you get in positioning these pieces is one

small raised ledge on one fuselage half. After several frustrating

minutes of trying to dry fit the interior bits in place, I took my

best guess and tacked them together using small dabs of CA. It took

a couple tries, but I finally positioned them to my satisfaction. I

then used liberal amounts of CA to firmly join them together.

The only other major challenge in the cockpit

was the instrument panel. Czech Model provides this in three

pieces: a center panel and two small side panels. Again, there is

very little indication of how these are supposed to fit together. I

had no photos of the prototype cockpit, so I just took my best guess

and installed them so they looked about right.

Once all the cockpit pieces were installed, I

painted them (again, taking an educated guess as to the proper

colors) and used a dark gray watercolor wash to accent all the nooks

and crannies. I used some ProModeler decals for the dials on the

instrument panels. Sometimes, these look a little too bold to me,

but they sure are a lot neater then anything I could paint.

Next, I tackled the engine exhaust stacks. The

XP-56 was powered by a radial engine buried inside the fuselage.

This configuration resulted in a prominent ring of exhaust stacks

around the rear of the fuselage, represented on the kit by simple

depressions in the plastic. I drilled out these dents and used

small sections of brass tubing (painted appropriately) to represent

the stacks. The tubing is held in place by blobs of Miliput on the

inside of the fuselage.

The aft end of the fuselage contains a simple

circular plate to which the propellers are attached. I used three

pieces of brass tubing, one inside another, as shafts for the

props. This allows both props to spin independently (not really a

necessary feature, but it was kind of fun to do). I also used

sections of fine wire to represent the linkages that controlled the

cowl flaps. Most photos of the XP-56 show the cowl flaps open, but

I wasn’t feeling that ambitious.

I added several lead fishing weights inside the

nose then joined the fuselage halves together. The fit here wasn’t

great, particularly along the lower fuselage. I spent several

sessions filling and sanding before I was happy with the seams.

Final Assembly and Painting

Once all the detail work and subassemblies were

done, construction proceeded rather quickly. I joined the wings to

the fuselage and checked all the seams. I also took the time to run

a scriber through all the panel lines. On my kit, some of the lines

were rather shallow and, in a couple spots, were totally filled in.

A quick rinsing, and I was ready to paint.

I painted the lower fuselage with Polly Scale

Neutral Gray and the upper fuselage with Model Master Acryl Olive

Drab. The top of the fin was painted insignia yellow (the kit

supplies a decal for the fin tip, but I thought it would look better

painted).

Next, I sprayed on a coat of Polly Scale clear

gloss and applied the kit decals. Then I sprayed another coat of

clear gloss to seal the decals, followed by a wash of dark gray

watercolor to accent the panel lines. Finally, I sealed everything

up with a coat of Polly Scale clear flat.

Other then some exhaust staining, I kept

weathering to a minimum since the XP-56 flew only ten times before

being grounded. After everything was dry, I attached the landing

gear and antenna, dropped in the prop and there it was: the XP-56.

Conclusions

I was quite pleased with this little model.

There are a few tricky steps, but its relatively simple

configuration (no tail surfaces, no under wing stores) makes it a

good choice for anyone wanting to try a limited-run kit. Its

distinctive shape also makes it stand out from all those other World

War Two fighters on my shelf.